Savings on investment

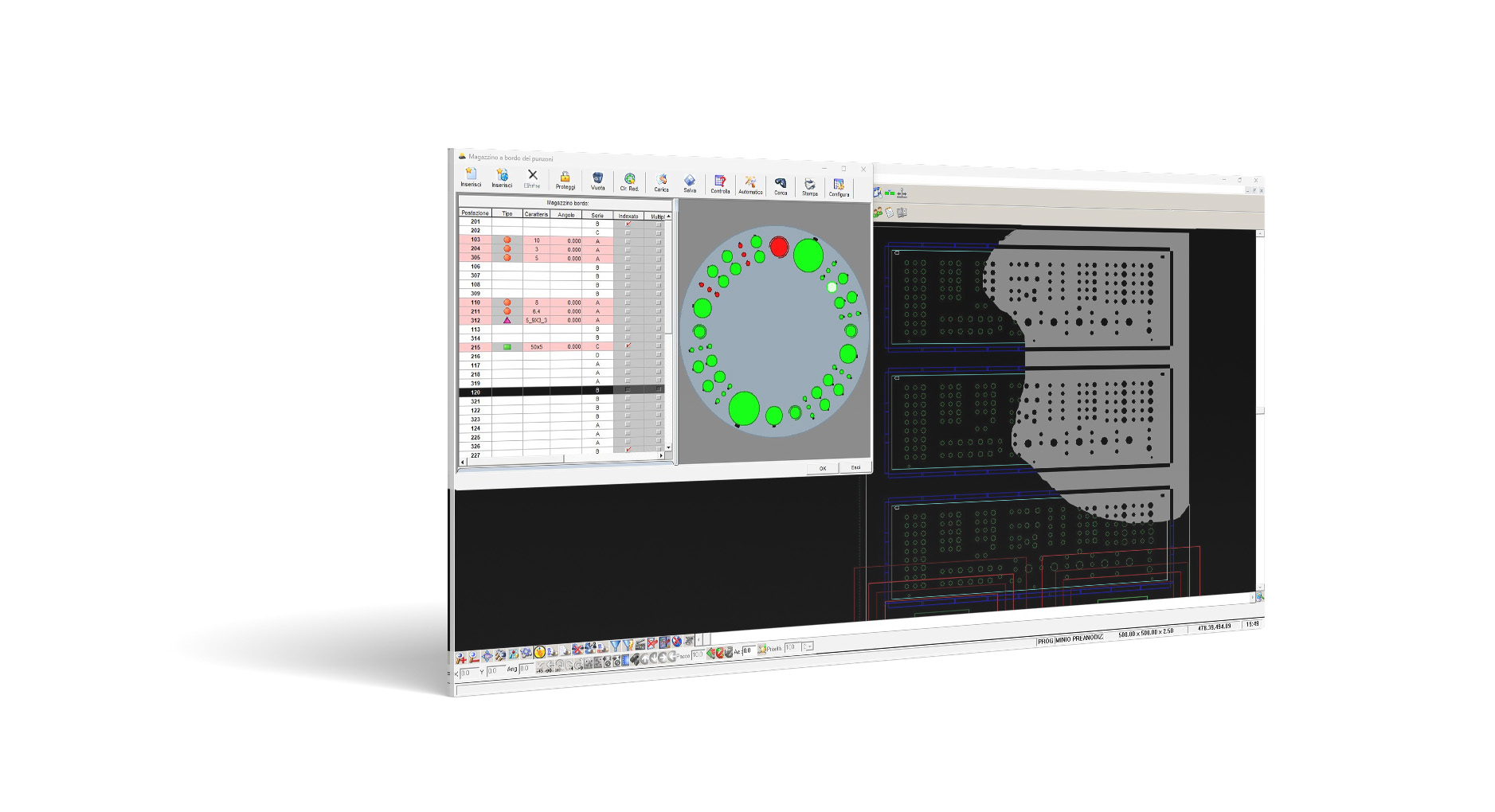

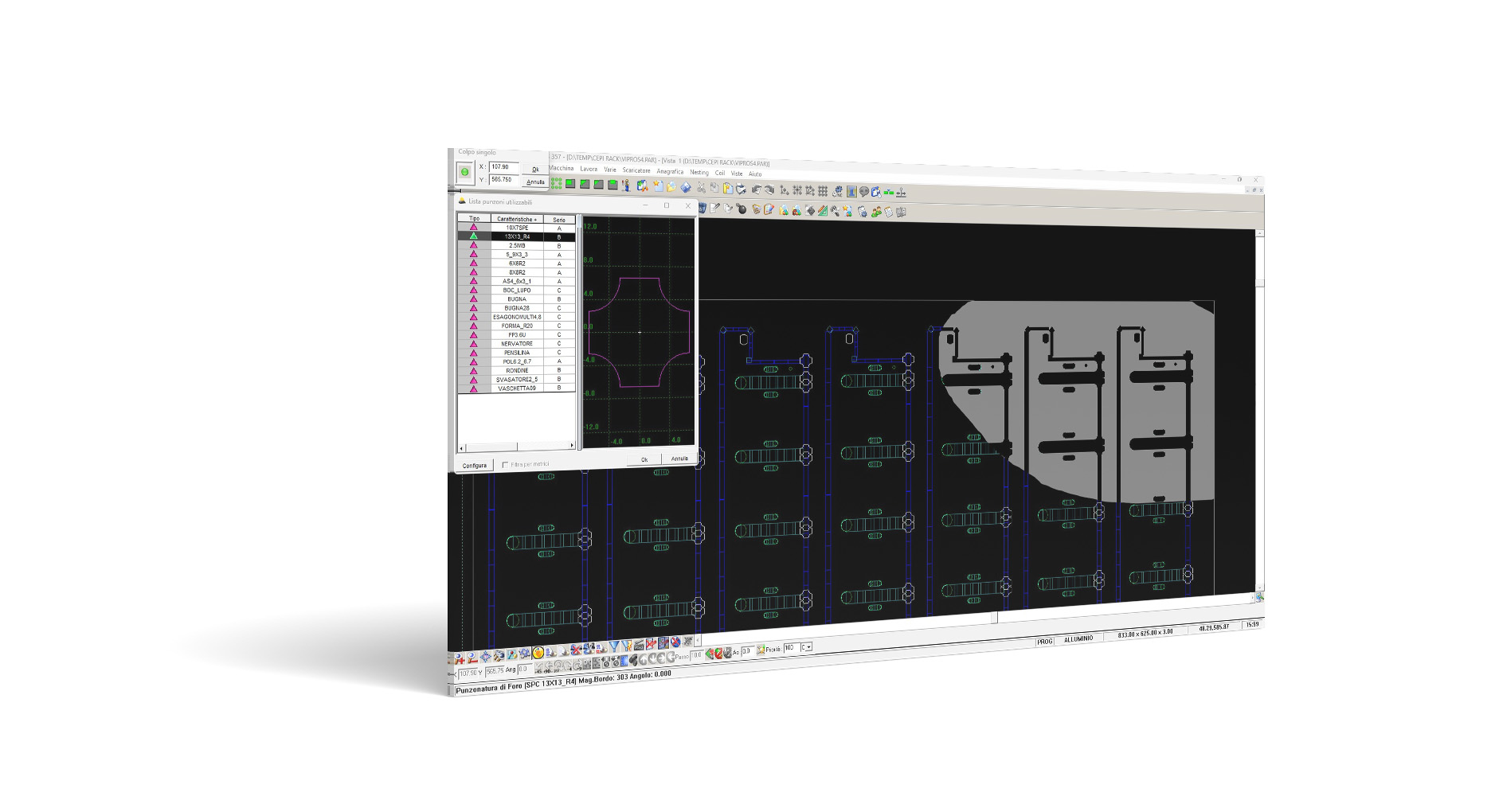

Projects, punches and cuts with one CAM software.

Import DXF from any CAD or create your own project by directly applying the operations in a simple and intuitive interface, accessible to any operator even without computer skills.

Reduction of processing times and tool wear

Thanks to the automatic processing of geometries and the intelligent sorting that creates the best and fastest production plan, you save time on machine setup and minimize tool wear and material stress.

Less scrap, more marginality

Minimize scrap and waste with AXI NEST, the functionality that can be integrated into CAM Computes AXI CAM program to manage automatic and optimized cutting plans.

+1000 MACHINES ALREADY CONNECTED

Decades of experience in the workshop have allowed Computes Group to develop the top-of-the-range CAM software for punching: stable, reliable, fully operational from the first day of training.

Do you have many machines from different manufacturers?

No problem, Computes AXI CAM generates NC code for machines from any manufacturer.

The advantages of punching

Automatic geometry processing

The CAM program autonomously chooses the best punch, which requires fewer strokes and/or causes less tool wear.

Reduction of machine setup times

The processing can be based on the entire tool range or only on those already mounted in the turret.

Management of any ounch and special punches

There is no limit to the management of the most complex punches, forming tools, grid tools, writing tools ( Maltese cross, dovetail, roller and roller tools with the management of multiple passes at different heights, louvers, etc..)

Automatic calculation of repositioning of thr clamps.

In case the processing is larger than the working area of the machine.

Micro-Joint management

Thanks to the intuitive interface, the user can decide the micro-joint points. It is also possible to define them using special punches such as the "dovetail".

Saving on machine wear

Thanks to the various types of intelligent sorting according to the processing needs, the machine will limit to the minimum necessary some movements ( rotation of the tool turret, punch and die change, movements of the carriage and clamps ), prolonging the life of the mechanical components.

The advantages of laser cutting

Automatic application of preset rules and finishes

Preset according to the thickness of the material and characteristics of the required processing

The software automatically interprets the processes to be carried out on a specific material and thickness and applies the correct rule based on these detected parameters.

Optimized Sorting

avoids overheating of the sheet metal and minimizes cuts.

Common cuts

It is possible to optimize the processes by saving time thanks to the programming of common cuts on multiple pieces.

Automatic cutting plans

Minimize scrap with the Automatic Nesting functionality available thanks to the integration with AXI NEST.

Other advantages

Automatic and manual management

It is possible to work automatically or with manual commands; the operator can intervene at any time to modify, for example, the repositioning or the punching order.

Management of auxiliary devices

The software manages sheet or single piece towers or unloaders, interfacing with any loading and unloading machinery.

CAM programming without geometry

Don't have a CAD or an experienced designer? No problem! It is possible to apply the technology functions directly thanks to a simple and intuitive interface. This procedure simplifies and reduces the time of all processes.

Check before producing

With the realistic simulation of all operations automatically, the CAM software allows a rapid control of the program, before sending it to the machine.

Manages customs macros

for example for the management of special profiles, useful especially for repetitive processes.